Rotary Steerable System (RSS) – drilling technology

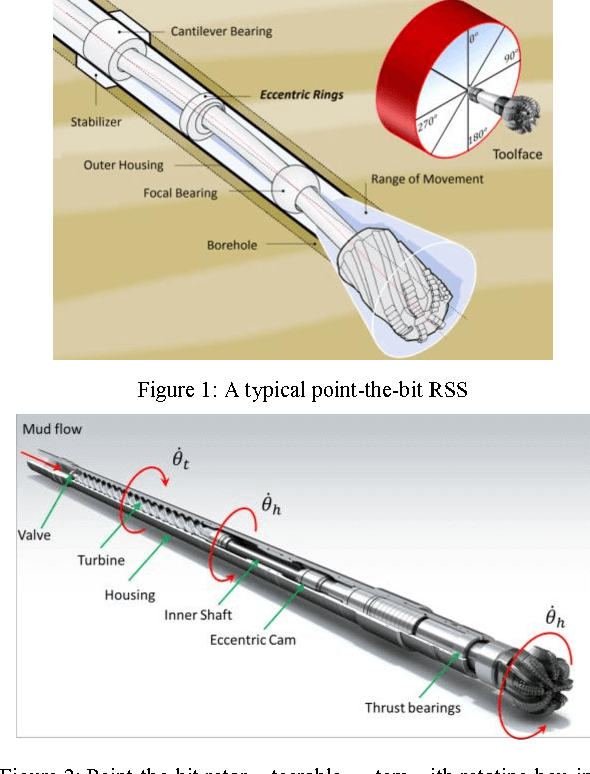

Rotary steering system (RSS) is a drilling technique used in directional drilling. It uses specialized downhole equipment to replace conventional directional tool mud motors.

They are usually programmed by measurement-while-drilling (MWD) engineers or directional drillers. They use surface equipment (usually using pressure fluctuations in the mud column or changes in the rotation of the drill string) to send commands to react to the tool and gradually turn to all required directions. In other words, the tool is designed to continuously rotate directional drilling from the ground, eliminating the need for a “sliding” mud motor.

The rotary steering system originally developed for drilling extended-reach horizontal wells has also achieved good economic benefits in conventional drilling because it can significantly shorten the drilling time. With the continuous development of rotary steering drilling technology and the continuous expansion of the market, rotary steering drilling technology is gradually becoming a common drilling method for wells with complex structures.

Different oilfield service companies:

1. Schlumberger’s PowerDrive rotary steering system includes three types: push-to-type (PowerDrive Orbit), directional (PowerDrive Xceed) and hybrid (PowerDrive Archer). The Schlumberger push-to-lean rotary guidance system has been upgraded from the original PowerDrive Xtra to PowerDrive X5 and PowerDrive X6, and has now been upgraded to PowerDrive Orbit.

2. Baker Hughes’ AutoTrak Non-Rotating Closed-Loop Drilling System (RCLS) is a static push-on rotary steering system. It consists of a two-way communication system (surface monitoring computer, decoding system and drilling fluid pulse signal generator) and steering system (AutoTrak tool) and LWD. Including AutoTrak G3, AutoTrak X-treme, AutoTrak eXpress, AutoTrak Curve

3. Halliburton’s Geo Pilot rotary steering drilling system is also a non-rotating outer barrel steering tool, but unlike AutoTrak and PowerDrive, the GeoPilot rotary steering drilling system does not rely on offset drills for steering, but does not rotate the outer barrel and rotating mandrel. A set of biasing mechanisms in between biases the rotating mandrel, thereby providing the drill bit with an inclination angle that is inconsistent with the borehole axis, thereby producing a steering effect. Including Geo-Pilot, iCruise

4. Weatherford Rotary Steerable System with continuous near-bit measurement and bidirectional downhole communication, you can make informed, real-time drilling decisions. Including Revolution, Magnus

5. Domestic China has mature rotary steerable systems which already were used in the fields. Including CG-STEER, SINOMACS ATS I, TORSION DRILLING, Welleader etc.

Please contact info@sennavs.com for more information. You can also click WhatsApp directly for model choosing or model recommendation.